- Nashik, India

- +917507123490/93/94

- Nashik, India

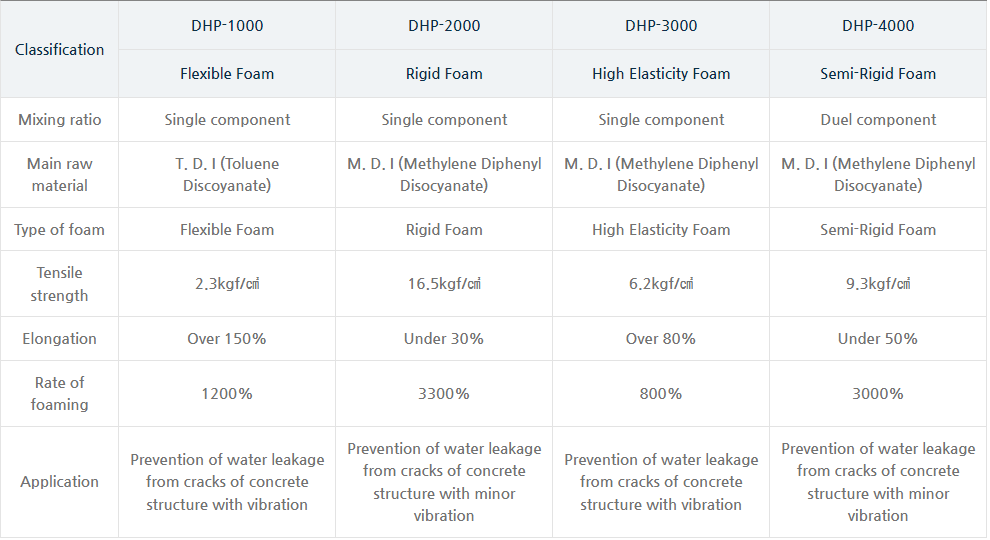

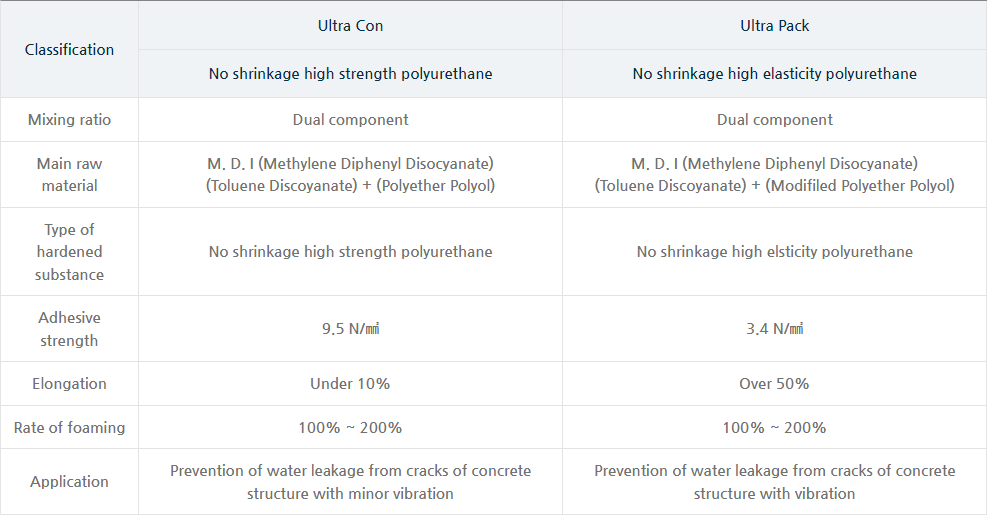

Polyurethane Foam Resin Grouting Method

Polyurethane foam resin grouting method is a kind of work process in which foam resin is injected with the pressure of over 10kgf/cm² into cracks or air voids of defective concrete structures to prevent water leakage, or into the defective parts of under- ground structure or dam to prevent water leakage that has been caused by excessive water pressure. grouting chemical for concrete Polyurethane foam resin so injected makes a reaction when it meets water and immediately creates foam, which contains the gushing water of high pressure and blocks the water leakage from minute crack to ensure waterproof

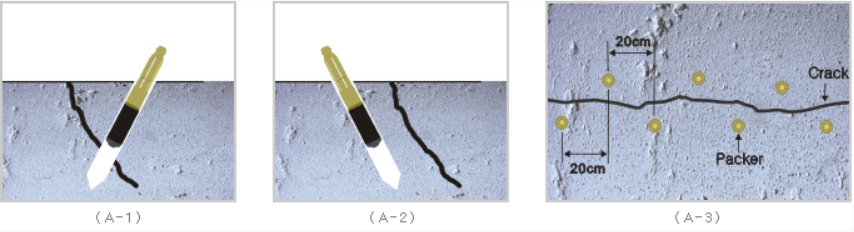

Polyurethane foam resin has a low viscosity, so you can inject it completely into the cracks or minute air voids in which water leakage is progressing by using high pressure injection pump.You are recommended to drill holes on the areas of water leakage at regular intervals and to use the packer with high pressure nozzle that we have developed to ensure that the foam resin makes a perfect infiltration into cracks or minute air voids. grouting chemical for concrete You can choose from a variety of packers depending upon the site condition.

After installing the packer, the drilling of the concrete surface must be cracked to be equal to or greater than 60 degrees, as can be seen in the picture above. The location of the drilling must be 10cm from the area of leakage to ensure that even the smallest spaces of the central crack can be entirely blocked. (According to the construction site, the angle or location of drilling may differ) The intervals between the drilling must be adjusted according to the width of the crack or the amount of water leakage. grouting chemical for concrete The drilling must be done in a zigzag shape from the crack. The intervals between the drilling must not exceed 20cm.

Hydroguardian India was founded with a mission to provide top-quality grouting chemicals and solutions that make structures leak-proof.

09:00 Am - 11:00 Pm

© 2024 Hydroguardindia Pvt. Lt.