- Nashik, India

- +917507123490/93/94

- Nashik, India

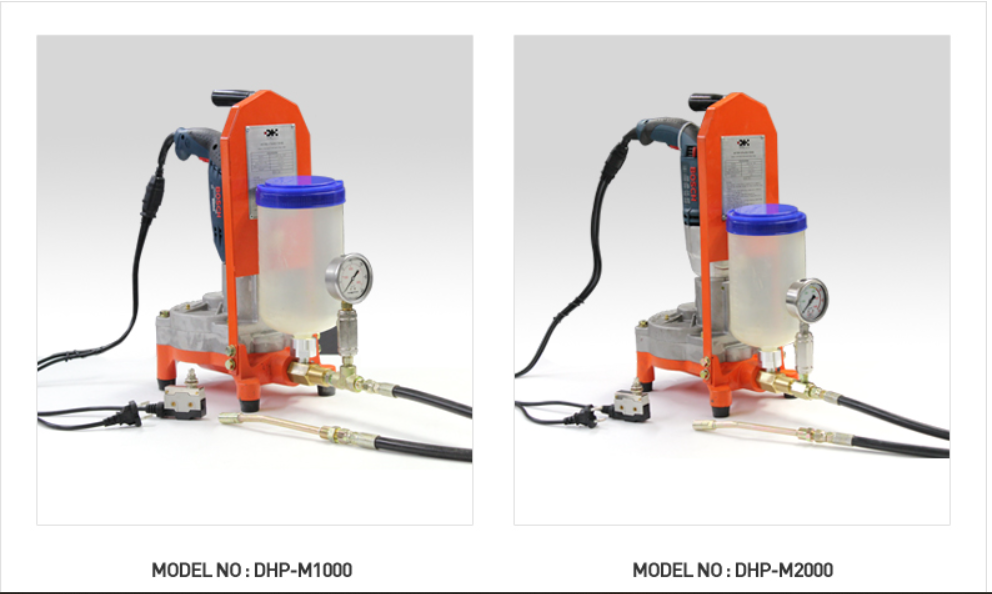

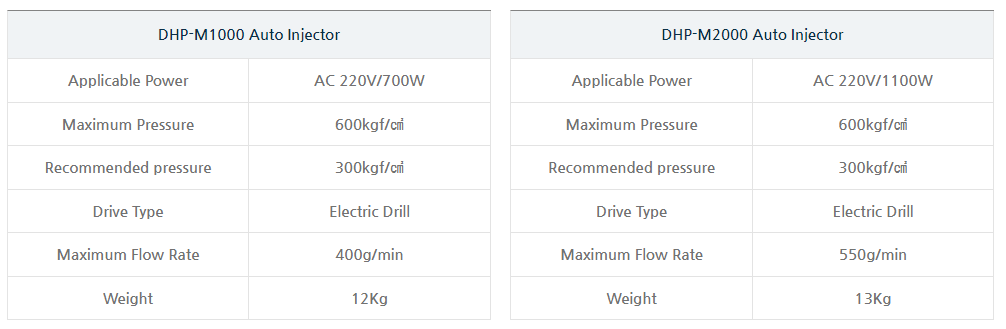

High pressure grouting injection pump for Epoxy Resin and Polyurethane injection Electric Drill Operated Injection Pump

High Pressure 7500PSI Grouting Injection Pump

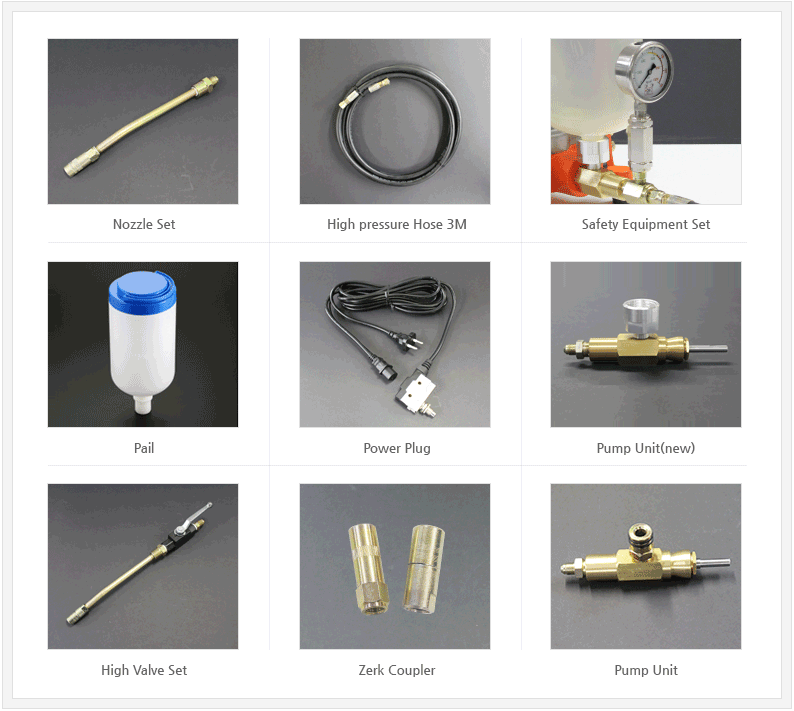

DHP-M1000/M2000 automatic injector is a single type high pressure injector designed to apply urethane resin and epoxy injection material to the crack part. grout injection pump As this electronic injector is easy to handle, easy the change consumables, and compact, while providing high discharging pressure, it is widely used in con- crete repairing and reinforcing works

Acrylic Injection Pump(DHP-M2002) is a twin line injection pump that discharges A type B type acrylic resins separately. It’s

made of SUS material acids considering the characteristics of acrylic resins.

DHP-M3000Acrylic Injection Pump (DHP-M3000) is a twin line injection pump that discharges A type and B type acrylic resins separately. It’s made of SUS material to resist acids considering the characteristics of acrylic resins. As its maximum injection pressure is 430kg/㎠, users can have an effect when injecting to joint parts and slav, beam. Also it has a proper size for rear grouting work and crack leakage injection.

Hydroguardian India was founded with a mission to provide top-quality grouting chemicals and solutions that make structures leak-proof.

09:00 Am - 11:00 Pm

© 2024 Hydroguardindia Pvt. Lt.